1. Introduction

In modern architecture and interior decoration, composite materials are widely used due to their excellent weather resistance, environmental friendliness, and aesthetic appeal. Co-extrusion composite cladding is an advanced composite material that plays a significant role in building facades and interior decoration. The sliding table saw, as a high-precision and high-efficiency cutting tool, greatly facilitates the processing of co-extrusion composite cladding. This article explores the combination of these two and analyzes their advantages and processing key points.

2. Characteristics of Co-extrusion Composite Cladding

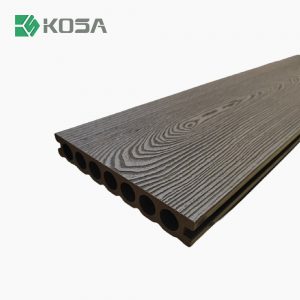

Co-extrusion composite cladding is a multilayer composite material manufactured using co-extrusion technology, typically consisting of wood-plastic composite (WPC), PVC, or other polymer materials with a high-polymer protective layer. Its main features include:

- High weather resistance: The surface is specially treated to provide UV resistance, oxidation resistance, and waterproof performance, making it suitable for outdoor environments.

- Environmental friendliness: Made from recyclable materials, it releases no formaldehyde and meets green building standards.

- Aesthetic variety: Can simulate natural materials such as wood and stone, offering a rich selection of colors and textures.

- Low maintenance cost: Requires no regular painting or anti-corrosion treatment and has a long service life.

3. Advantages of the Sliding Table Saw in Processing Co-extrusion Composite Cladding

A sliding table saw is a high-precision industrial cutting tool widely used for wood, plastic, and composite material cutting. Compared to traditional handheld saws, the sliding table saw offers several advantages when processing co-extrusion composite cladding:

- Precise cutting: Equipped with sliding rails and a stable cutting table, ensuring accurate dimensions and reducing errors.

- High efficiency: Faster than traditional saw benches or handheld tools, improving production efficiency.

- Smooth cutting edges: The high-speed rotating blade ensures smooth cutting edges, minimizing the need for subsequent sanding.

- Multi-angle cutting: The adjustable-angle feature is suitable for different design requirements, such as bevel joints and embedded installations.

- High safety: The protective devices and sliding table design reduce operational risks and enhance processing safety.

4. Key Points for Cutting Co-extrusion Composite Cladding

When using a sliding table saw to process co-extrusion composite cladding, the following points should be considered to ensure the best cutting results:

- Choose the right blade: It is recommended to use a tungsten carbide-tipped (TCT) blade with a moderate number of teeth to minimize chipping.

- Control feed speed: Excessive feed speed may cause rough cuts, while too slow a speed may generate excessive heat, affecting material quality.

- Fix the material properly: Ensure the cladding is stably placed on the sliding table saw to prevent movement or vibration that could affect cutting precision.

- Use a dust collection system: Cutting co-extrusion composite materials produces fine dust, so a good dust collection system helps maintain a clean working environment.

- Be mindful of heat effects: High-speed cutting may cause melting or deformation of the material, so intermittent cutting can help reduce heat impact.

5. Conclusion

The widespread application of co-extrusion composite cladding has driven the demand for efficient and precise processing tools. The sliding table saw, with its high precision and efficiency, is an ideal choice for cutting this material. By selecting the appropriate blade, controlling cutting parameters, and implementing safety measures, processing quality and efficiency can be greatly improved, providing more innovative possibilities for the architectural decoration industry.

In the future, with advancements in composite material technology and the development of intelligent processing equipment, the combination of co-extrusion composite cladding and sliding table saws will become even more prevalent, offering superior solutions for modern architecture and decoration.