1. Technical Breakdown: How Co-Extrusion Redefines Industry Standards

1.1 Core Innovation of Co-Extrusion Technology

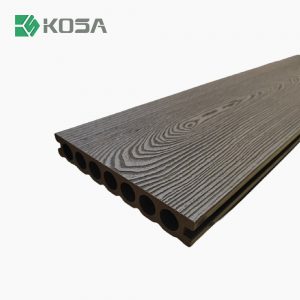

By synchronously extruding dual (or multi) layers, co-extrusion bonds a high-density polymer cap layer with a recycled wood-plastic composite (WPC) core, creating a “rigid-yet-flexible” structure. The cap layer provides UV resistance, moisture protection, and scratch resistance, while the core enhances load-bearing capacity and reduces costs.

1.2 Critical Upgrades Over Traditional WPC

Fade Resistance: UV inhibitors in the cap layer reduce color fading by 80% compared to single-layer WPC (ASTM G154 data)

Crack Resistance: Dual-density structure limits thermal expansion to 0.5mm/m·°C, eliminating traditional WPC’s “cracking syndrome”

Maintenance Revolution: Non-porous surface prevents mold growth, cutting cleaning costs by 60%

2. Market Trends: The Logic Behind Global Demand Surge

2.1 Data-Driven Insights

Grand View Research reports the global co-extrusion decking market reached $4.2B in 2023, with an 11.3% CAGR (2024-2030)

42% of North American homeowners prioritize “low-maintenance decking” in remodels (HomeAdvisor 2023 Survey)

2.2 Shifting Design Preferences

Luxury projects like Miami EDITION Hotel’s terrace use co-extrusion wood-grain boards, fueling the “naturalist minimalist” trend. Advanced texturing now achieves 3D embossed oak grains and hand-scraped finishes.

3. Cost Efficiency Reimagined: Full Lifecycle Analysis

|

Metric |

Hardwood |

Single-Layer WPC |

Co-Extrusion |

|

Initial Cost ($/sq.ft) |

4.18-6.03 |

3.25-4.65 |

5.11-6.97 |

|

Annual Maintenance |

$1.11-1.67 |

$0.46-0.74 |

$0.14-0.28 |

|

Lifespan (Years) |

10-15 |

15-20 |

25-30+ |

Source: IBHS Building Cost Database

Conclusion: Over 30 years, co-extrusion decking costs 58% less than hardwood, with a 4-6 year ROI.

4. Sustainability Debates & Groundbreaking Innovations

4.1 Solving the Carbon Footprint Paradox

Material Innovation: Leaders like Trex use 95% recycled plastics + wood fibers—each sq.ft recycles ~500 plastic bags

Closed-Loop Systems: Brands like Kebony develop recyclable co-extrusion formulas for cradle-to-cradle cycles

4.2 Remaining Challenges

Higher thermal conductivity (requires improved core foaming tech)

Premium pricing for custom colors (22%-35% cost increase)

5. Installation Revolution: Hidden Clip Systems

Next-gen UniLink™ and SpeedLock™ systems enable:

Tool-Free Installation: Reduces labor time by 90%

Dynamic Drainage Channels: Self-adjusting slope handles 5L/min·m water flow

Thermal Expansion Compensation: ±8mm lateral movement tolerance

Future Outlook: Smart Co-Extrusion Possibilities

Lab-stage breakthroughs include:

Phase-Change Temperature Control: Microencapsulated wax regulates surface heat

Self-Healing Coatings: Nano-polymers auto-repair micro-cracks

Integrated Solar Tech: Transparent co-extrusion layers embed flexible PV films (17% efficiency)